As material prices, transportation fees, tariffs, and global supply chain disruptions continue to drive up costs across industries, many companies are re-evaluating where and how their products are made. For businesses that rely on precision parts, metal manufacturing in Minnesota offers significant advantages, especially when combined with the efficiencies of lean manufacturing. At Whirltronics, we understand that every dollar matters. That’s why our customers trust us to deliver high-quality, cost-effective metal parts manufactured right here in Minnesota.

Why Local Metal Manufacturing Matters

Outsourcing overseas might seem like a cheaper option up front, but hidden costs often pile up quickly. By choosing a Minnesota-based manufacturer, businesses gain several long-term advantages:

- Lower Shipping Costs: Domestic production eliminates costly overseas freight charges, tariffs, and unpredictable delivery delays.

- Faster Lead Times: Local manufacturing means parts arrive quickly, helping you keep production schedules on track.

- Stronger Communication: Working in the same time zone (and often face-to-face) ensures better collaboration and fewer costly errors.

- Reliable Quality Standards: U.S.-based manufacturers follow strict regulations and quality control measures that protect your product integrity.

In today’s unpredictable market, those advantages add up to real savings and stability.

Lean Manufacturing: A Smarter Way to Control Costs

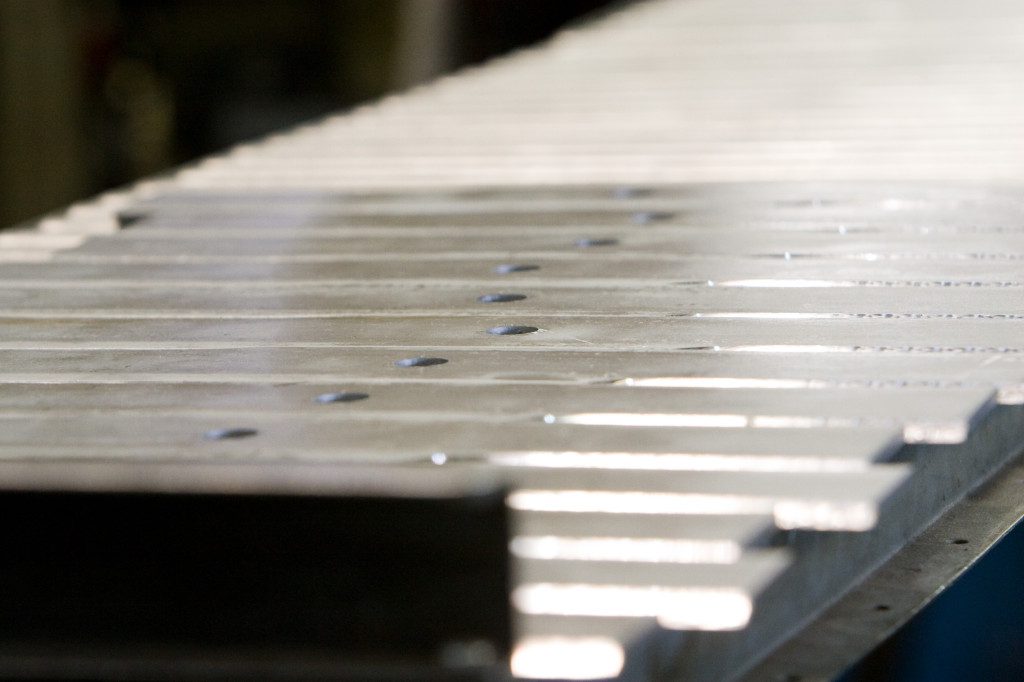

At Whirltronics, we take those benefits one step further with our lean manufacturing practices. Lean manufacturing focuses on eliminating waste, streamlining processes, and maximizing efficiency, all while maintaining precision and quality.

Here’s how lean manufacturing helps keep costs in check:

- Reduced Material Waste – Every cut, press, and stamp is optimized to make the most of raw materials.

- Improved Workflow Efficiency – Organized production flow means fewer delays, less downtime, and faster turnaround.

- Lower Energy Use – By focusing on efficiency, we cut back on unnecessary energy consumption, which lowers overhead.

- Consistent Quality – Fewer defects and reworks mean lower costs for our customers.

The result? More value for every dollar you spend, without compromising the strength, accuracy, or durability of your metal parts.

Why Whirltronics Is the Right Choice

For more than 60 years, Whirltronics has been a trusted metal manufacturing partner in Minnesota. We specialize in precision stamping, forming, custom tooling, austemper heat treating, prototyping, and lean production processes that help our customers stay competitive even as costs rise.

By keeping your manufacturing local and partnering with a company committed to lean principles, you gain:

- High-quality, American-made parts

- Cost savings from efficient production methods

- Shorter lead times and reliable delivery

- A team dedicated to continuous improvement

Keep Your Manufacturing Competitive

As costs continue to rise across the industry, choosing the right manufacturing partner is more important than ever. By working with Whirltronics, you get the value of local Minnesota manufacturing combined with the cost-control power of lean practices. Ready to see how lean manufacturing can lower costs and improve your products? Contact Whirltronics today to start the conversation.