When your project demands precision, strength, and reliability, you need a partner that understands the art (and science!) of metal forming. Whirltronics provides industry-leading metal forming services that combine advanced technology with expert craftsmanship to deliver durable, custom-engineered components built to perform.

What Is Metal Forming?

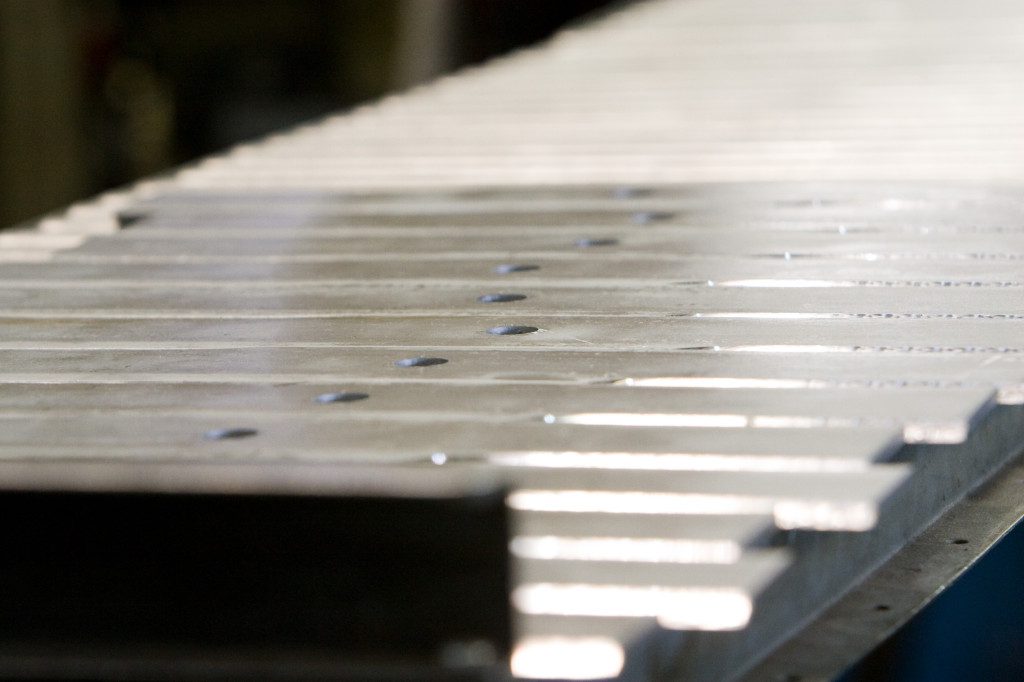

Metal forming is a process that shapes raw steel into strong, functional parts for both structural and non-structural applications. Whether you’re manufacturing components for heavy machinery, industrial equipment, or custom projects, the forming process determines the integrity, strength, and cost-efficiency of the final product.

At Whirltronics, our metal forming capabilities allow us to handle a wide range of steel thicknesses, giving clients flexibility in design and performance. Our team helps you choose the most economical and effective forming method for your specific material, requirements, and finish.

Precision Forming for Complex Shapes

Not every part is simple, and that’s where Whirltronics excels. Our advanced forming processes make it possible to shape heavy-gauge steel into intricate, complex forms without cracking or compromising structural integrity. Whether your design includes deep bends, curved contours, or unique geometries, our forming experts ensure every component meets exact specifications. The result? Durability, precision, and consistency every single time.

Engineering Expertise from Start to Finish

Our engineers collaborate closely with clients to design custom metal parts that meet precise application needs. From concept to completion, we work to optimize materials, reduce waste, and ensure that each part is formed to exact tolerances.

With Whirltronics, you’re not just getting parts, you’re getting a manufacturing partner that understands how to turn your ideas into efficient, high-quality solutions.

A Trusted Name in Metal Manufacturing

Proudly located in Buffalo, Minnesota, Whirltronics is an ISO 9001 Certified manufacturer committed to lean manufacturing principles and excellence at every stage of production. Every part we produce is made in the USA, ensuring high-quality craftsmanship, efficient production, and consistent results.

Our team combines advanced technology, precision engineering, and lean processes to minimize waste, maximize value, and deliver the most cost-effective solutions for our customers. Whether it’s metal forming, fabrication, or prototyping, Whirltronics ensures precision and reliability in every component.

Why Choose Whirltronics for Metal Forming?

- ISO 9001 Certified for consistent quality and process excellence

- Lean manufacturing practices that increase efficiency and reduce waste

- Proudly made in the USA at our Buffalo, MN facility

- Advanced metal forming capabilities for a wide range of steel thicknesses

- Custom part design and engineering support from concept to completion

- Precision shaping of complex, heavy-gauge materials

- Durable, high-quality results that meet your performance standards

- Economical manufacturing solutions tailored to your needs

At Whirltronics, we take pride in being a trusted American manufacturer, where lean manufacturing, ISO-certified quality, and precision metal forming come together to create reliable, cost-effective solutions for every project. Contact our team for a quote to get started on your project today!

Follow us on Facebook | Find us on LinkedIn | Subscribe to our newsletter