3 ways you will benefit from our tool room expansion and new CNC machine

Whirltronics is growing and we are investing right back into our manufacturing. This will deliver more efficient results and a more effective service to our customers. With these small additions, we can support our clients with a large range of services while saving them money in the process.

Check out these 3 ways you can benefit from our tool room expansion and new CNC machine:

- Strengthens our model for vertical integration

Adding more space and equipment to our facility grows the diversity of Whirltronics creating huge potential for our clients. All tooling can be designed and built in-house giving more control to the manufacturing process while lowering the overall cost.

- Increases our customer speed to market

With the expanded capabilities for us to build tooling and room for more manufacturing, our customers’ speed to market dramatically increases. Whirltronics wants to keep our clients ahead of their competition by providing effective and timely turnarounds from prototyping to full run productions.

- Creates a WIN/WIN with our tool making team & our customers

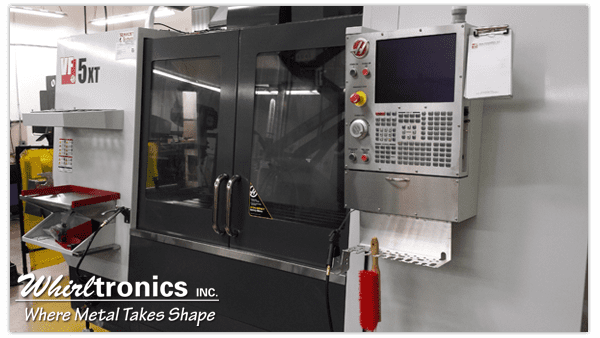

Our newly acquired Haas CNC machine brings more effectiveness to our tooling production team by minimizing waste and maximizing our time efficiency. This significantly accelerates our turnaround times for projects while staying within budget. A new CNC machine also enhances our tool making precision by being able to operate consistently and accurately to produce quality products every time.

Are you thinking about your next project yet? Learn more about how Whirltronics can help you take the next step forward today by calling (763) 682-1716.